In addition to the increasingly important environmental aspect, the Huber E-Drive / Hybrid Team focuses on modular, customised, intelligent solutions, high performance and resilience, even under demanding conditions.

YOUR MOTIVATION IS OUR PASSION

E-DRIVE AND HYBRID TEAM

This division offers complete solutions for E-Mobility and Hybrid vehicle concepts for special markets. The developments in this segment refer to the integration of intelligent control systems into the overall vehicle and comprises the central vehicle control of all system-relevant components.

Already in 2011, thanks to the scope of the subsidized „ELENA“- plug-in hybrid for light industrial vehicles (trucks and vans) project, our company was able to become very familiar with the subject of hybrid drive and high-voltage systems and thereby be able to develop know-how and experience at a very early phase of our entry into this diverse field.

More knowledge relating to the complete architecture of such systems was acquired whilst we developed another demonstration vehicle with a pure electric drive for the mining industry. This comprised of both the integration of an entire Battery System and the design of its cooling system.

Today, Huber Automotive as established specialist for Automotive Electronics profits in its E-Drive solutions from many years of experience as Tier-1 supplier in the automotive industry. State-of-the art large-series technology in all fields of applications are possible thanks to a great number of system designs and integrations of electrified and hybrid power trains and profound knowledge in the intelligent networking of control units and -onboard architectures and last but not least many years of partnerships with renowned European system suppliers of the automotive industry. One system innovation is the Huber E-Drive as a plug-in hybrid concept. In vehicles with a combustion engine and front-wheel drive, an electric drive is integrated in the rear axle. With the Hybrid Power Chassis – a joint project in cooperation with chassis manufacturer AL-KO – we have realized a compact and weight-optimized form of electrification, providing an optimal mobility solution for the noiseless and zero-emission operation of transport vehicles and motorhomes in urban areas.

PROJECTS

HYBRID POWER CHASSIS

COOPERATION

WITH AL-KO FAHRZEUGTECHNIK

E-TRAILER-PLATFORM

ONE CHASSIS

– MANY NEW POSSIBILITIES

MINE

CHANGER

100% POWER

0% LOCAL EMISSION

GKN

E-POWERTRAIN

ALL-TWINSTER

PLUG-IN HYBRID

ELECTRIC SOLUTIONS FOR EACH SITUATION

E-DRIVE AND HYBRID TEAM

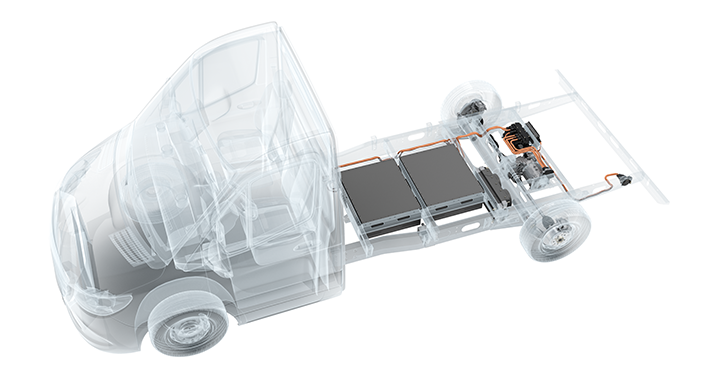

HYBRID POWER CHASSIS

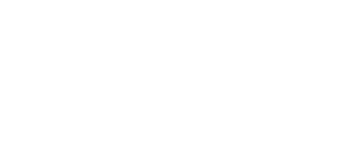

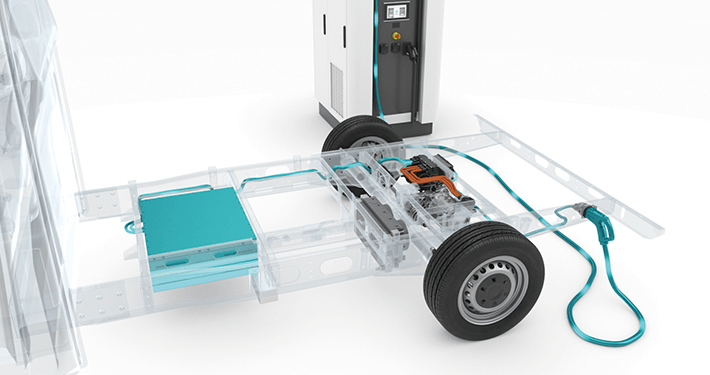

The Hybrid Power Chassis enables emission-free, all-electric driving for motorhomes and light commercial vehicles based on a Fiat Ducato powerhead. With a gross vehicle weight rating of 3.5 to 5.0 tonnes, the Hybrid Power Chassis is the perfect solution for zero-emission urban electric drive and longer, off-highway combustion engine tours. The special feature: The electrified rear axle with an output of approximately 90 kW can be switched on when needed, making the van the first light commercial vehicle with a hybrid concept.

It is based on the AL-KO lightweight chassis, which as a system platform enables modular deployment of battery packs and components while at the same time protecting the batteries. That allows the battery capacity to be adapted, according to the customer’s needs, to a range of up to about 100 km with fully electric drive. For routes over longer distances, such as overland tours, the vehicle’s combustion engine can be used without restrictions.

- World premiere at the IAA 2018: Hybrid Power Chassis

- Hybrid system with plug-in technology

- Zero-emissions urban transport and combustion-powered overland tours

HIGHLIGHTS

• Additional traction drive for off-road travel

• 4×4 starting aid (e.g. for wet ground or hill starts in winter)

• Booster (better acceleration with fuel savings up to 30%)

• Energy recovery for power supply to the vehicle body

• Generator function to power additional electric components of the vehicle body

• Power supply for various additional loads (air conditioning, cooling, heating, etc.)

YouTube Videos

Insight into the project realization:

ENGINEERING

BATTERY STACKS

Scalable battery stacks with

range up to more than 100 km

POWER PLUG-IN

Charging current connection

POWERTRAIN MODULE

Electric rear axle drive

with a power of 90 kW

CHARGER

High-performance onboard charger

with charging capacity of 7 kW or optionally 22 kW (230 V/400 V)

POWER ELECTRONICS

Power electronics

HED-MANAGER

Hybrid Electric Drive Management

IMAGES

FURTHER INFORMATION E-TRAILER

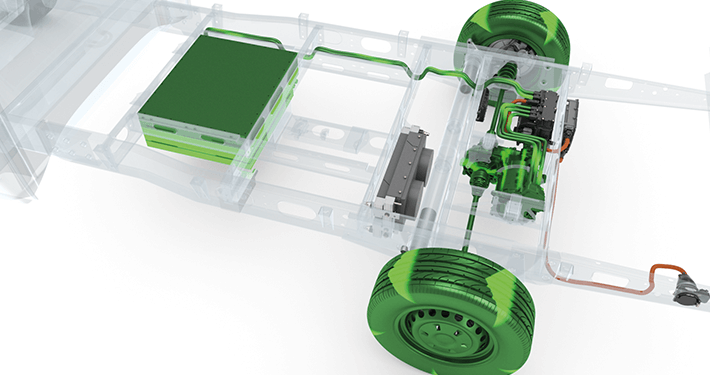

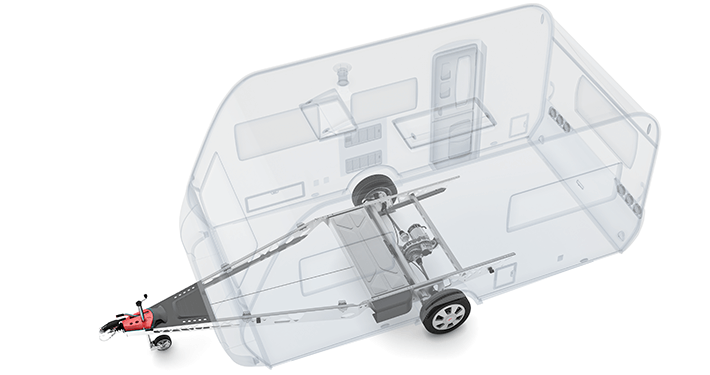

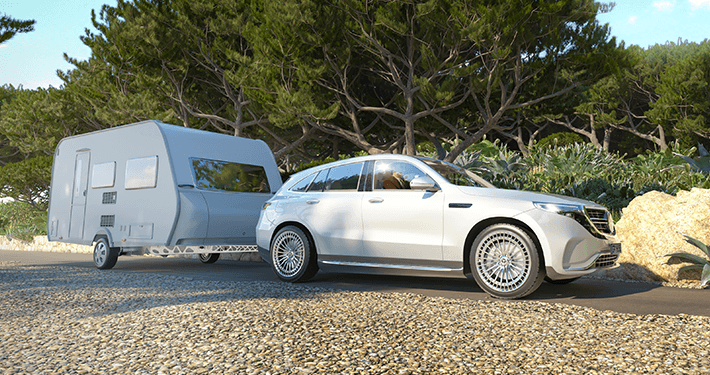

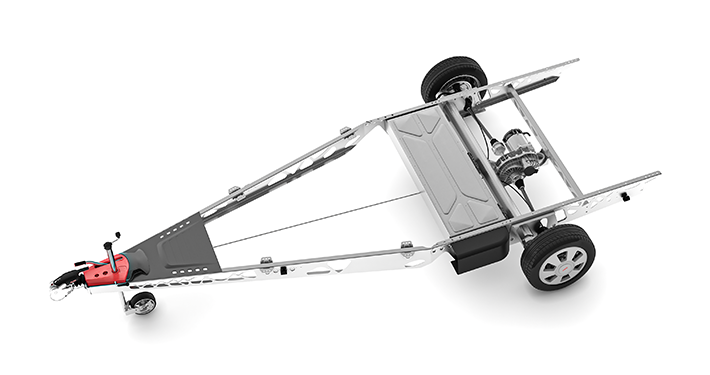

E-TRAILER PLATFORM

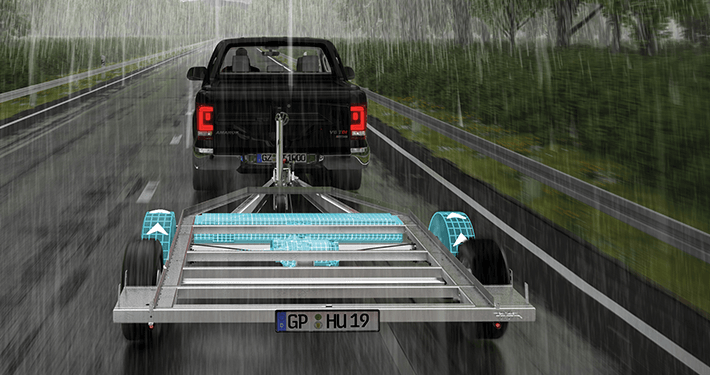

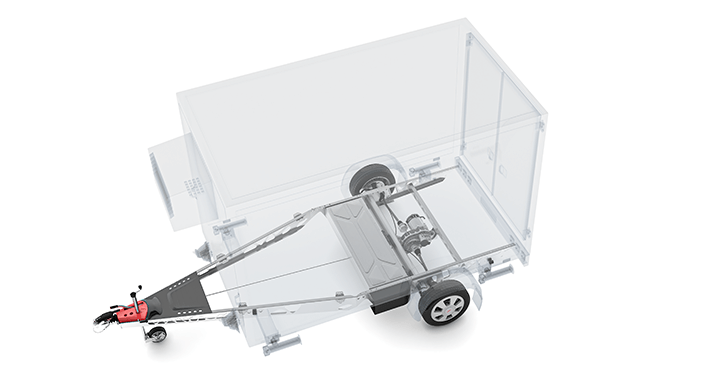

The feature-packed trailer of the future – A total of 9 different functions enable an environmentally friendly, comfortable and safe way to be on the road with the trailer.

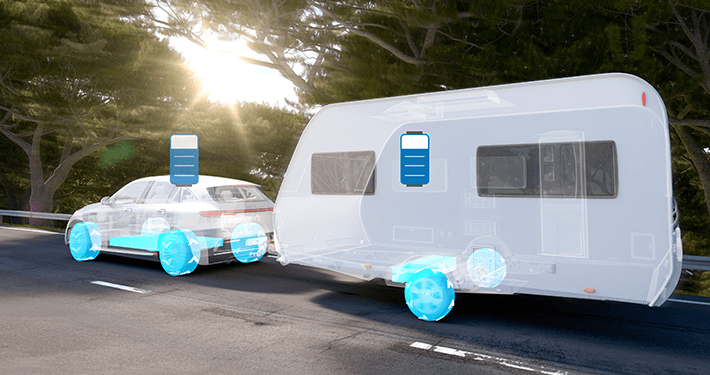

The latest development of the Huber E-Drive family extends the application possibilities of modern mobility in many areas. No matter whether it is about the range of electric vehicles or the consumption optimisation of hybrid or combustion vehicles, as soon as these are used as towing vehicles for trailers, the range or consumption increases noticeably.

The aim of the Huber E-Drive for trailers is to minimise these restrictions and to noticeably improve the usability of utility and leisure trailers.

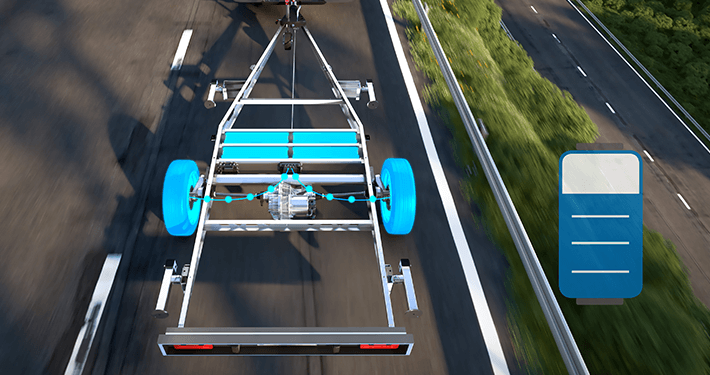

Based on a 48V system with modular battery packs, this slim system can be installed in almost any trailer chassis. Thanks to intelligent sensors, the trailer always „knows“ where it is in relation to its towing vehicle.

Equipped with a modern, lightweight transmission in conjunction with the 48V electric machine, the trailer follows in a strain-relieving manner and thus makes a significant contribution to maintaining the range of an electric vehicle or optimising the fuel consumption of hybrids and combustion engines.

As soon as the sensors detect a speed reduction, the system switches from drive to recuperation and thus recovers valuable energy.

However, Huber‘s E-Drive system for trailers does much more than simply optimising the range. One of the biggest risks in trailer operation is the „rocking“ of the trailer, whether due to road conditions or sudden evasive manoeuvres. With the Huber E-Drive for trailers this risk is reduced, the sensors combined with the intelligent Huber control system detect the driving situation at lightning speed and intervene with the optionally available „Torque Vectoring“, an individual speed control per wheel. Of course, the system can also be used as a starting and traction aid on wet or slippery surfaces. They can easily get out of campsites or damp meadows.

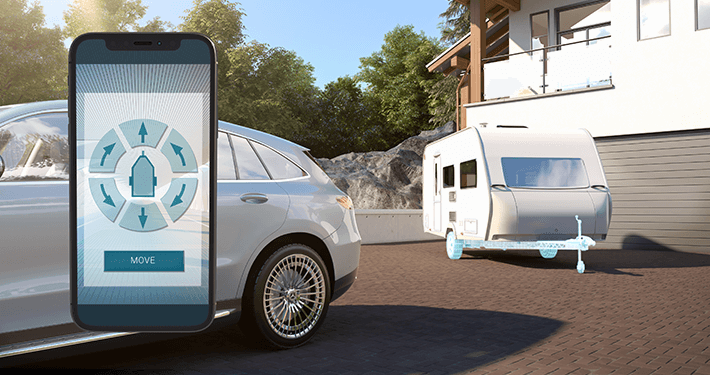

Further advantages for the user also arise with, partly completely new, comfort functions. Equipped with a WLAN control unit, the trailer becomes a semi-autonomous, remote-controlled all-rounder.

As you park the trailer with the vehicle, the rear view camera automatically turns on when reversing and is displayed on the connected mobile device. If precise parking with the vehicle is not possible, simply use the app provided for this purpose. With the integrated remote control you can manoeuvre the trailer into the desired position independently. Of course, this system also supports you during the towing process.

Completely new possibilities for the professional use or also the caravan individualist result from the carried energy stores. When the trailer is parked, they are simply used as a backup battery, which supplies the respective body with energy when there is no power supply. Whether cooling unit, light, multimedia or kitchenette, the Huber E-Drive bridges the supply gap depending on the selected memory size.

Another important additional function of the system is the optional anti-theft device. Activated via the app, the gearbox is electromechanically locked and towing by unauthorised persons is effectively prevented.

The electrification of a trailer gives the user a multitude of previously unavailable options, safety features and, above all, range and consumption optimisation.

YouTube VIDEO

ENGINEERING

SCALABLE BATTERY SYSTEM

SMART SYSTEM-ARCHITECTURE

System Control

48 V ELECTRIC AXLE DRIVE

With Torque Vectoring

SURROUNDINGS SENSOR SYSTEM

IMAGES

WEITERE INFORMATIONEN E-TRAILER

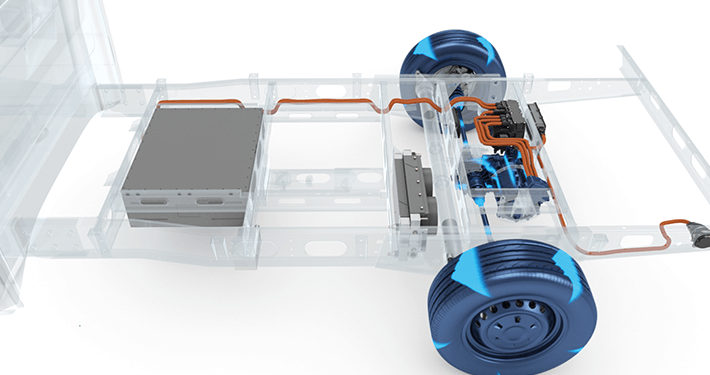

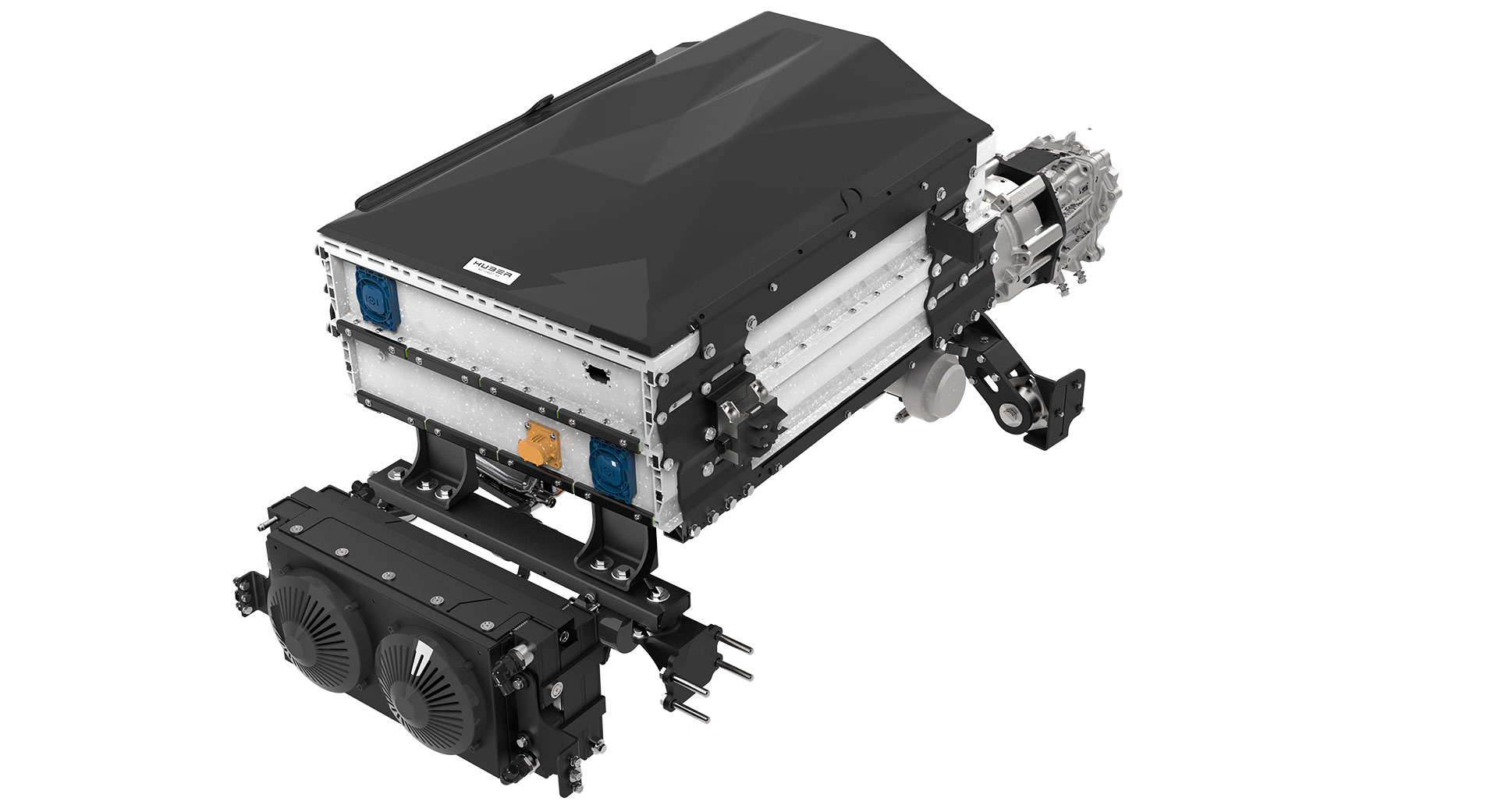

MINE CHANGER

The electrified version of the Toyota Land Cruiser has been conceived for use in extreme environments and remains a 2WD/4WD vehicle with and without gear reduction – ideal for use in rough terrain, especially in underground mining.

The e-drive system comprises standard components from leading suppliers, for example from Bosch. These are arranged into a new architecture that best exploits their individual strengths. This is all made possible thanks to the core element of the system, Huber’s innovative control unit that uses a 32-bit power architecture to extract peak performance from the individual components under ideal thermal conditions. In the brand-new update of the already successful E-Drive Kit, a for Heavy-Duty developed 35 kWh battery pack is installed.

Solution for improved occupational safety in underground mining: “The vehicle is perfectly matched to the conditions in underground mining.” Uwe Blättermann K+S AG, Scoop Magazine 1/2017 The electric version enables zero-emission driving, enormously improving health protection for employees – especially in mining.

HIGHLIGHTS

- System architecture: System components from well-known German TIER-1 suppliers arranged in a new architecture.

- System management: vehicle control and integration of system electronic components by self-developed intelligent control unit (developed according to ECE R 100; CE)

- Efficiency: Cost savings through reduced maintenance and operating costs

- Performance: Range 120 km; Electrical power 90 kW/ 60 kW; Charging time 1.5 h; Gradeability 45 %.

YouTube VIDEO

ENGINEERING

POWERTRAIN MODULE

POWER MODULE

COOLING MODULE

A-WING MODULE

IMAGES

FURTHER INFORMATION MINE CHANGER

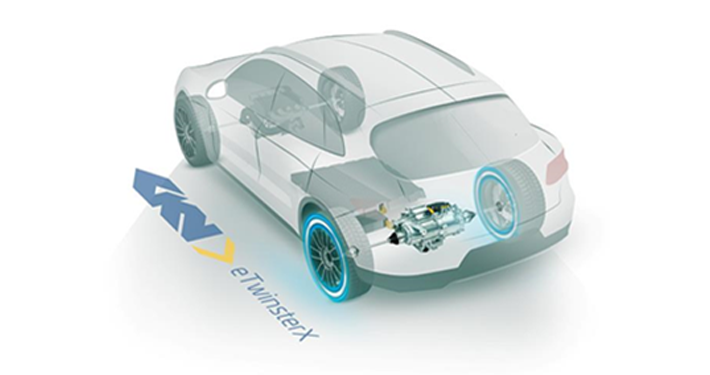

GKN E-POWERTRAIN

Conceptual design and integration of GKN ePowertrain modules for “ALL-TWINSTER PLUG-IN HYBRID”

This project demonstrates the integration competence of Huber Automotive in existing vehicle concepts: a vehicle with a combustion engine and front-wheel drive gets an additional electric drive on the rear axle.

HIGHLIGHTS

- Torque vectoring

- Extension to all-wheel drive

- Gateway functionality in the basic vehicle architecture to enable various special and additional functions

- Independent of charging infrastructure

- Braking energy recovery

- 400 kW “Hybrid-Electric high performance drive”

- Driving modes: Electrical, Hybrid, Combustion

- Flexible ICE charging with 18 kW generator

- Two-stage transmission

IMAGES

FURTHER INFORMATION ALL TWINSTER PLUG-IN-HYBRID